[et_pb_section fb_built=”1″ fullwidth=”on” module_class=”service_banner” _builder_version=”3.22″ custom_margin=”0px||0px|” custom_padding=”0px||0px|”][et_pb_fullwidth_code custom_margin=”0px|||” custom_padding=”0px|||” custom_css_main_element=”padding-top: 0px !important”]

[/et_pb_fullwidth_code][/et_pb_section][et_pb_section fb_built=”1″ custom_padding_last_edited=”on|desktop” _builder_version=”3.22″ custom_padding_tablet=”” custom_padding_phone=”” custom_css_main_element=”clear: both;”][et_pb_row column_structure=”1_2,1_2″ module_class=”SameHeight_cust” _builder_version=”3.25″][et_pb_column type=”1_2″ module_class=”vertical-align MblCenter_cust ” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_text admin_label=”Siemens Servo Motor Repair” _builder_version=”3.27.4″]

Accu Electric Servo Motor Repair

[/et_pb_text][et_pb_text _builder_version=”3.27.4″ custom_margin=”-14px|||” custom_margin_tablet=”-14px||20px|” custom_margin_phone=”” custom_margin_last_edited=”on|phone”]Since our origin in 1993, we have serviced over 200,000 units of servo motors. We are the go-to service provider thanks to our being ISO:9001 Quality Assurance and CSA explosion proof repair certified facility with more than 20 years of experience. Our unique approach to Siemens servo motor repair is yet another key reason why we have amassed immense popularity in North America.

[/et_pb_text][/et_pb_column][et_pb_column type=”1_2″ module_class=”vertical-align” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://www.accuglobal.com/wp-content/uploads/2019/12/siemens-servo-motor.jpg” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”4.0.7″ hover_enabled=”0″ always_center_on_mobile=”on”][/et_pb_image][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ custom_padding_last_edited=”off|desktop” _builder_version=”3.22″ background_color=”#f2f2f2″][et_pb_row column_structure=”1_2,1_2″ custom_padding_last_edited=”off|tablet” module_class=”SameHeight_cust” _builder_version=”3.25″][et_pb_column type=”1_2″ module_class=”vertical-align” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2018/05/Siemens-Servo-Motor-blue-print.jpg” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”3.23″ custom_margin_tablet=”||20px|” custom_margin_phone=”” custom_margin_last_edited=”on|tablet” custom_padding=”0px|||” custom_padding_tablet=”” custom_padding_phone=”” custom_padding_last_edited=”on|phone” always_center_on_mobile=”on”][/et_pb_image][/et_pb_column][et_pb_column type=”1_2″ module_class=”vertical-align MblCenter_cust ” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_text admin_label=”Servo Motor Repair” _builder_version=”3.27.4″]

Why Accu Electric Inc.

[/et_pb_text][et_pb_text _builder_version=”3.27.4″ custom_margin=”-14px|||” custom_margin_tablet=”” custom_margin_phone=”” custom_margin_last_edited=”on|phone”]Prior to starting work on a servo motor, our team thoroughly evaluates your motor to identify the exact cause of failure. All the mechanical and electrical parts are inspected. The evaluation focuses on housing fits, bearing fits, worn shafts, corroded or broken flanges and effective hall sensors and the AC tachometer output. Our team of more than 15 engineers and 45 employees acts on this information to fix the exact motor problem. Problems are addressed by re-manufacturing or repairing the parts that don’t meet factory specifications.

Once the repairs are done, preliminary testing is the step that follows. Numerous tests are done throughout the repair and assembly process to ensure everything is in line with manufacturer’s specifications. Often times, our assembly process improves internal motor components due to the use of advanced components such as high-grade sealed bearings and new seals. Final testing follows after assembly.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ custom_padding_last_edited=”on|phone” _builder_version=”3.22″ custom_padding=”80px||80px|” custom_padding_tablet=”50px||50px|” custom_padding_phone=”40px||40px|”][et_pb_row column_structure=”1_2,1_2″ module_class=”repair_sec” _builder_version=”3.25″ custom_width_px=”1480px”][et_pb_column type=”1_2″ _builder_version=”3.25″ custom_padding=”|||” custom_css_main_element=”margin: 0 !important;” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2017/11/Servo-Motor-03.jpg” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”3.23″ custom_margin=”||40px|” custom_margin_tablet=”” custom_margin_phone=”||30px|” custom_margin_last_edited=”on|desktop” border_color=”#e5e5e5″ border_width=”10px” always_center_on_mobile=”on”][/et_pb_image][et_pb_text module_class=”TextRight_cust ” _builder_version=”3.27.4″ text_text_color=”#010101″ text_orientation=”right” module_alignment=”right” custom_padding=”|65px||” custom_padding_tablet=”|40px||” custom_padding_phone=”|30px||” custom_padding_last_edited=”on|phone”]

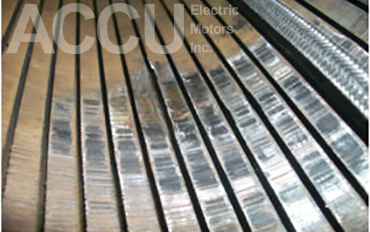

Widing Analysis

[/et_pb_text][/et_pb_column][et_pb_column type=”1_2″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_text module_class=”TextRight_cust ” _builder_version=”3.27.4″ custom_padding=”60px|||55px” custom_padding_tablet=”35px|35px||” custom_padding_phone=”” custom_padding_last_edited=”on|desktop”]

With over $75,000+ invested in our winding analysis equipment, we catch

[/et_pb_text][et_pb_text module_class=”repair_box” _builder_version=”3.27.4″]Winding can fail over an extended period of time, and without proper testing equipment, it is

hard to determine the cause.

- Early phase to ground leakage

- Phase to phase leakage

- Resistance imbalance between phases

- Inductance imbalance between phases

- Impedance imbalance between phases

- Phase angle imbalance between phases

[/et_pb_text][/et_pb_column][/et_pb_row][et_pb_row custom_padding_last_edited=”on|tablet” _builder_version=”3.25″ background_size=”initial” background_position=”top_left” background_repeat=”repeat” custom_padding=”83px|||” custom_padding_tablet=”53px|||” custom_padding_phone=””][et_pb_column type=”4_4″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_tabs active_tab_background_color=”#214599″ inactive_tab_background_color=”#f6f6f6″ _builder_version=”3.0.87″ tab_text_color=”#141414″ body_font=”Oswald||||||||” body_text_color=”#5d5d5d” body_font_size=”17″ body_line_height=”26px” tab_font=”Oswald|300|||||||” tab_font_size=”17″ tab_line_height=”26px” custom_padding=”51px|40px|51px|40px” custom_css_tabs_controls=”min-height:0;” border_width_all=”1px” border_color_all=”#e4e4e4″ border_style_all=”solid” use_border_color=”on” border_color=”#e4e4e4″][et_pb_tab title=”Magnetizing in House” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]Magnetizing is a key component with most stepper and pancake motors. Due to the type of magnets in stepper motors, when the rotor is removed from the stator the magnetic properties of the rotor are lost. Without the latest magnetizing equipment, most repair shops cannot repair these jobs.

- Capable of magnetizing N55 grade neodymium rare earth magnets

- Fixtures for almost all sizes of rotors ready in stock

- Required for pancake motor, and stepper motor repairs

- Fixes many low torque issues with machines

Typically your servo, stepper or pancake motor incurring damage due to an overloaded system, causing a high current fault. This high current spike will cause the magnets in your motor to become demagnetized. Once demagnetized your motor may run, but with diminished torque. Under full load your system will fail. Another scenario in which damage is incurred is by opening the stepper or pancake motor. There is a specific air gap between the magnets in the stator and the rotor itself, if this air gap is lost (IE. by the removal of the rotor) demagnetization will occur.

By magnetizing the rotor after assembly, a high flux density is obtained that can be largely destroyed if the rotor is removed.

Thus by re-magnetizing your servo motor, stepper motor or pancake motor you will be assured that your motor will have the same torque output as it did when shipped from the manufacturer.

In this case BOSCH was unable to repair their own motor due to extreme damage. However, we were able to rebuild this motor in 24 hours to get the client up and running with manufacture matched specifications.

[/et_pb_tab][et_pb_tab title=”Machining In House” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]

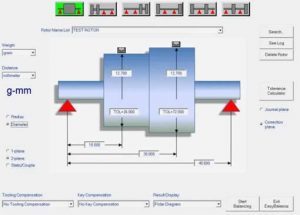

Full time dedicated machinists in shop allows us to repair industrial automation equipment with the highest quality standard. Not taking shortcuts we insure all our products are well fitted to manufacturer specifications.

- In house dedicated machinist

- Designs by mechanical engineers

- New shaft installation and repair

- Retrofitting in house

Since we are outfitted with a Machine shop, we do not need to send any work out, thus we keep our repair cost down, and are not dependent on someone else to complete repairs.

[/et_pb_tab][et_pb_tab title=”Balancing In House” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]

Often after repair of magnets and other rotor related faults, balancing is lost. Resulting in a vibrating noisy motor.

Our in-house balancing insures your motor will run smooth and quite the first time you plug it in.

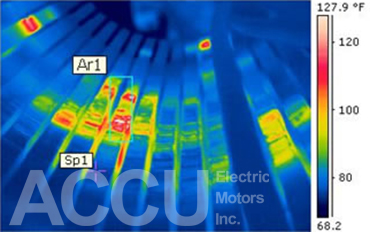

[/et_pb_tab][et_pb_tab title=”Infrared Analysis” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]One of the most effective measures for preventative maintenance is infrared technology. With it we can determine faults in areas such as:

- Bearings and bearing housings

- Overheating winding

- Overcurrent

- Hot spots in breakers, contactors, fuses, transformers & more.

- Coreloss testing (as shown below)

[/et_pb_tab][et_pb_tab title=”Feedback Devices Repair” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]

Looking for a place to get your feedback device tested, or repaired? We specialize and are certified in all industrial automation feedback. Resolvers, incremental encoders, absolute encoders, linear encoders, optical encoders, hall sensors, tacho generators, texans, and more.

With over $400, 000 inventory of feedback devices, if we can’t repair your encoder, we can replace it.

[/et_pb_tab][et_pb_tab title=”Run Tests” _builder_version=”3.0.86″ body_font=”||||||||” tab_font=”||||||||”]With over a million invested in testing of servo motors, we now house the most operational servo drives in North America.

All servo equipment is run tested on it’s manufacture designated servo drive to insure correct operation the first time. Outfitted with testing software and hardware of all major brands. Stocking over $400,000 in feedback devices such as Resolvers, Encoders, Tachs.

We own over 30 robots and CNC machines that we use for full load run tests of devices like motors, pulse encoders, amplifiers, drives, power supplies, CPU boards, I/O boards, teach-pendants, displays, extended access units, reducers/gearboxes, all types of cables …

We run pumps with the appropriate liquid as water, coolant, oil or some other liquids prior for it to leave the shop.

[/et_pb_tab][/et_pb_tabs][/et_pb_column][/et_pb_row][et_pb_row column_structure=”1_2,1_2″ custom_padding_last_edited=”on|tablet” _builder_version=”3.25″ custom_padding=”80px|||” custom_padding_tablet=”50px|||” custom_padding_phone=””][et_pb_column type=”1_2″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_video src=”https://www.youtube.com/watch?v=aZPo7Q7W1ek” _builder_version=”3.0.86″][/et_pb_video][/et_pb_column][et_pb_column type=”1_2″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_text _builder_version=”3.27.4″]

Feedback Device Repair Capabilities Include

Being certified by various electric motor producers we provide repair services to all major brands and most minor feedback devices. We carry a large stock of all kinds of replacement parts from all major and most minor producers. Choosing Accu Electric Motors Inc. you are guaranteed to get the fastest top quality service.

[/et_pb_text][et_pb_toggle title=”Encoders” admin_label=”Encoders” _builder_version=”3.0.86″ title_text_color=”#303030″ title_font=”Oswald|300|||||||” title_font_size=”20″ title_line_height=”26px” body_font=”Oswald|300|||||||” body_font_size=”17″ body_line_height=”26px”]We provide you with both mechanical parts (including back covers) and electronic parts of encoders. We repair all types of encoders including:

- Incremental Encoders

- Mechanical Absolute Encoders

- Optical Absolute Encoders

- Magnetic Absolute Encoders

- Capacitive Absolute Encoders

- Battery-Powered Multi-Turn Encoders

- Geared Multi-Turn Encoders

- Geared Multi-Turn Encoders

[/et_pb_toggle][et_pb_toggle title=”Tachometers” admin_label=”Tachometers” _builder_version=”3.0.86″ title_text_color=”#303030″ title_font=”Oswald|300|||||||” title_font_size=”20″ title_line_height=”26px” body_font=”Oswald|300|||||||” body_font_size=”17″ body_line_height=”26px”]Do you have problems with your old Tachometers that are out of production? Then you came to the right place! We can always find new model that will fit just perfectly to your old motor. We can also repair your old tachometers. Up to you to decide.

[/et_pb_toggle][et_pb_toggle title=”Resolvers” admin_label=”Resolvers” _builder_version=”3.0.86″ title_text_color=”#303030″ title_font=”Oswald|300|||||||” title_font_size=”20″ title_line_height=”26px” body_font=”Oswald|300|||||||” body_font_size=”17″ body_line_height=”26px”]Are you troubled with your old resolver that is out of production? Then you have come to the right shop! We can sure provide a new model that will correctly fit to your old motor. At that we can repair your old resolver. It’s up to you to decide and save.

[/et_pb_toggle][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ module_class=”units_repaired” _builder_version=”4.0.7″ background_color=”#000000″ background_image=”https://www.accuglobal.com/wp-content/uploads/2017/11/ACCU-Electric-Motors-Inc-17.png” global_module=”308″][et_pb_row column_structure=”1_3,1_3,1_3″ _builder_version=”3.25″ background_size=”initial” background_position=”top_left” background_repeat=”repeat”][et_pb_column type=”1_3″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2017/11/ACCU-Electric-Motors-Inc-5.png” align=”center” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”4.0.7″ always_center_on_mobile=”on”][/et_pb_image][et_pb_text _builder_version=”3.27.4″]

200,000

Units Repaired

[/et_pb_text][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2017/11/ACCU-Electric-Motors-Inc-6.png” align=”center” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”4.0.7″ always_center_on_mobile=”on”][/et_pb_image][et_pb_text _builder_version=”3.27.4″]

85

Years Of Experience

[/et_pb_text][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2017/11/ACCU-Electric-Motors-Inc-7.png” align=”center” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”4.0.7″ always_center_on_mobile=”on”][/et_pb_image][et_pb_text _builder_version=”3.27.4″]

24

Hour Technical Support

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ custom_padding_last_edited=”on|phone” _builder_version=”3.22″ custom_padding=”80px||80px|” custom_padding_tablet=”50px||50px|” custom_padding_phone=”40px||40px|”][et_pb_row column_structure=”1_2,1_2″ make_equal=”on” custom_padding_last_edited=”on|tablet” _builder_version=”3.25″ custom_padding=”80px|||” custom_padding_tablet=”50px|||” custom_padding_phone=””][et_pb_column type=”1_2″ module_class=”vertical-align ” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_image src=”https://accuglobal.com/wp-content/uploads/2018/05/Siemens-Servo-Motor-Repair-1.jpg” align_tablet=”center” align_phone=”” align_last_edited=”on|desktop” _builder_version=”3.23″ custom_margin_tablet=”||20px|” custom_margin_phone=”” custom_margin_last_edited=”on|desktop” always_center_on_mobile=”on”][/et_pb_image][/et_pb_column][et_pb_column type=”1_2″ module_class=”vertical-align MblCenter_cust ” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_text _builder_version=”3.27.4″]Our team at Accu Electric Motors Inc. is committed to ensuring that the Siemens servo motor repair brings your motor back to the factory specifications so that it performs like you bought a brand new one. We have the manpower and resources needed to not just repair your motor to a ‘running’ condition but to ensure it performs at the factory standards.

We are here to solve your servo motor problems fast and within your budget. Give us a call today and let us know what the problem is. Our 85 years cumulative experience has enabled us to fix any motor issue even on proprietary brands.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ _builder_version=”3.22″ background_color=”#2c4793″][et_pb_row _builder_version=”3.25″ background_size=”initial” background_position=”top_left” background_repeat=”repeat”][et_pb_column type=”4_4″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_code _builder_version=”4.0.7″ text_orientation=”center”]

Servo Motor Repair Manufacturers

[/et_pb_code][et_pb_code _builder_version=”4.0.7″]

[/et_pb_code][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ module_class=”call_us_section ” _builder_version=”3.0.86″ background_color=”#f2f2f2″ custom_margin_tablet=”” custom_margin_phone=”” custom_margin_last_edited=”on|desktop” global_module=”498″][et_pb_row make_equal=”on” _builder_version=”3.25″ column_structure=”2_3,1_3″][et_pb_column type=”2_3″ module_class=”vertical-align” _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_blurb title=”Contact Us today, and get a free consultation!” content_max_width=”1200px” admin_label=”Contact Us today” _builder_version=”3.0.86″ header_font=”Oswald||||||||” header_text_color=”#000000″ header_font_size=”43″ body_font=”Oswald||||||||”][/et_pb_blurb][/et_pb_column][et_pb_column type=”1_3″ _builder_version=”3.25″ custom_padding=”|||” custom_padding__hover=”|||”][et_pb_button button_url=”https://accuglobal.com/contact-us/” button_text=”Contact Us” button_alignment=”center” _builder_version=”3.16″ custom_button=”on” button_text_size=”18″ button_text_color=”#ffffff” button_bg_color=”#214599″ button_border_width=”0″ button_border_radius=”0″ button_font=”Oswald|300||on|||||” button_use_icon=”off” custom_padding=”18px|68px|18px|68px” button_text_color_hover=”#ffffff” button_border_color_hover=”#000000″ button_border_radius_hover=”0″ button_bg_color_hover=”#000000″ button_text_size__hover_enabled=”off” button_one_text_size__hover_enabled=”off” button_two_text_size__hover_enabled=”off” button_text_color__hover_enabled=”on” button_text_color__hover=”#ffffff” button_one_text_color__hover_enabled=”off” button_two_text_color__hover_enabled=”off” button_border_width__hover_enabled=”off” button_one_border_width__hover_enabled=”off” button_two_border_width__hover_enabled=”off” button_border_color__hover_enabled=”on” button_border_color__hover=”#000000″ button_one_border_color__hover_enabled=”off” button_two_border_color__hover_enabled=”off” button_border_radius__hover_enabled=”on” button_border_radius__hover=”0″ button_one_border_radius__hover_enabled=”off” button_two_border_radius__hover_enabled=”off” button_letter_spacing__hover_enabled=”off” button_one_letter_spacing__hover_enabled=”off” button_two_letter_spacing__hover_enabled=”off” button_bg_color__hover_enabled=”on” button_bg_color__hover=”#000000″ button_one_bg_color__hover_enabled=”off” button_two_bg_color__hover_enabled=”off”][/et_pb_button][/et_pb_column][/et_pb_row][/et_pb_section]