ACCU

ELECTRIC

Serving USA & CANADA– For Expert Industrial Repairs, Call (888) 932-9183 or (905) 829-2505 Today!

ACCU

ELECTRICO

Serving MEXICO – For Expert Industrial Repairs, Call +52 449-968-5772 or +52 449-205 2700 Today!

Comprehensive Industrial Repairs, All Under One Roof

Gearbox Repair

Pump Repair

Servo Motor Repair

Robotics Repair

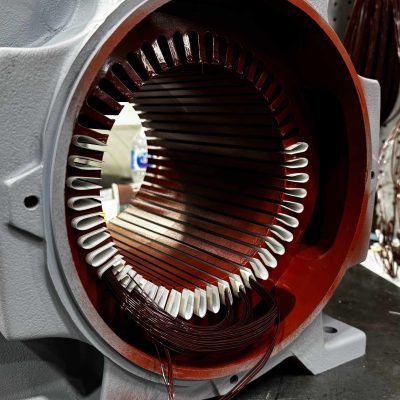

Electric Motor

Repair

Teach Pendant

Repair

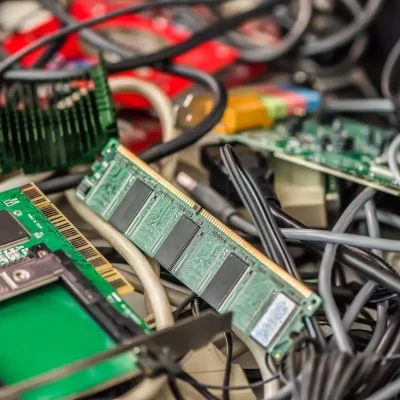

Industrial

Electronics Repair

Cable Solution

Services

Millwrighting

Services

Obsolete Part

Search

Machining

Services

Predictive

Maintenance

Gearbox Repair

Pump Repair

Servo Motor Repair

Robotics Repair

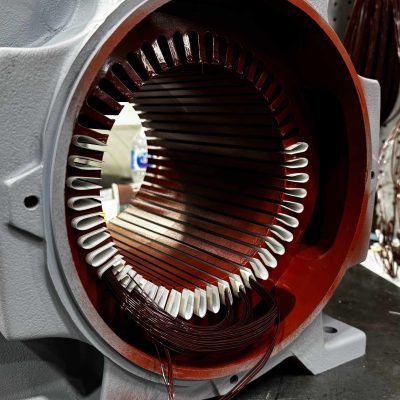

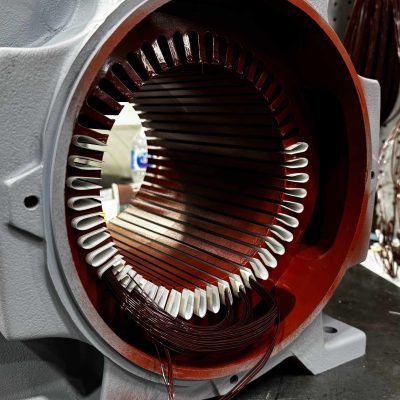

Electric Motor

Repair

Teach Pendant

Repair

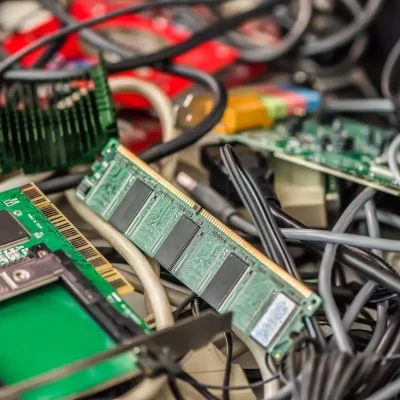

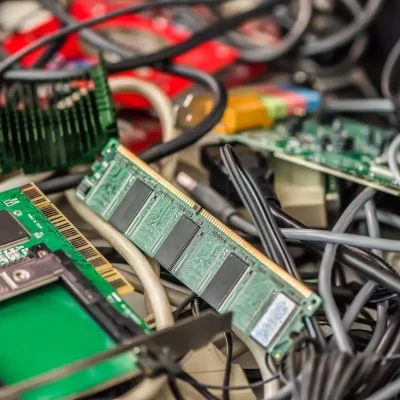

Industrial

Electronics Repair

Cable Solution

Services

Millwrighting

Services

Obsolete Part

Search

Machining

Services

Predictive

Maintenance

Gearbox Repair

Pump Repair

Servo Motor

Repair

Robotics Repair

Electric Motor

Repair

Teach Pendant

Repair

Industrial

Electronics Repair

Cable Solution

Services

Millwrighting

Services

Obsolete Part

Search

Machining

Services

Predictive

Maintenance

Most Active Brands Being Served

Why Accu Electric Inc.

- Accu Electric Motors Inc.: Driving Industrial Reliability

At Accu Electric Motors Inc., we are a leading provider of comprehensive industrial repair and maintenance services, specializing in electric motors, servo systems, and high-precision equipment. - Repair and Reconditioning Capabilities:

With over 30 years of experience, our skilled technicians are equipped to handle even the most complex repair and reconditioning challenges. Our state-of-the-art facilities house advanced machining capabilities, allowing us to refurbish, recondition, and reverse-engineer components with unparalleled precision. - Semiconductor Industry Solutions:

As a trusted partner to the semiconductor industry. - Customized Maintenance Programs:

We recognize that every facility has unique needs. - In-House and On-Site Services:

At our state-of-the-art repair facilities. - Committed to Excellence:

At Accu Electric Motors Inc., we are committed to delivering exceptional service. - Contact us today to learn how Accu Electric Motors Inc. can help drive the success of your industrial operations through our comprehensive repair, maintenance, and support services for motors, pumps, gearboxes, and other critical equipment

Customer's Feedback

ACCU has made a huge difference on our business. They can get you anything , from electrical to hydraulics. Very professional and reliable and very affordable. Thank you for getting us out of trouble so many times.

We've been using this vendor for many years and they have saved production for us on many occasions. Motors & gearboxes that were incredibly hard to find from other vendors were no problem for Accu Electric. Excellent experience with motor and gearbox rebuilds, even advanced electronic troubleshooting, PLCs, touchscreens/displays, servo motors, and on-site servicing are well within Accu's capabilities.

To top it off, we've had excellent service from Accu Electric for years. They're usually able to come in on emergency, they provide quick turnaround on repairs, and excellent communication from the staff gives us the confidence to continue doing business with them.

I sent them a motor that I was told by multiple venders was unrepairable, and obsolete. Their lead tech was very informative, and was able to offer me a quick turnaround by retrofitting newer components into my current repair. This was the most cost effective solution, and was able to get my machine up and running without having to upgrade the entire HMI